MINISTRY OF EDUCATION AND TRAINING

DA NANG UNIVERSITY

NGUYEN VAN TUAN

RESEARCH APPLICATION OF WASTE SMOKE HEAT FOR COOLING AND AIR CONDITIONING

ATMOSPHERE

Specialization: Thermal Technology Code : 60.52.80

SUMMARY OF THE MASTER OF TECHNOLOGY THESIS

Da Nang – Year 2013

The work was completed at

Maybe you are interested!

DA NANG UNIVERSITY

Scientific instructor: Dr. NGUYEN THANH VAN

Reviewer 1: Dr. Phan Qui Tra

Reviewer 2: Prof. TSKH. Phan Quang Chung

The thesis was defended in front of the Graduation Thesis Graduation Committee of Engineering meeting at the University of Danang on October 23, 2013.

Thesis can be found at:

- Center for Information - Study Materials, University of Danang

- Learning Resource Center, University of Danang.

PREAMBLE

1. Urgency of the topic

In the era of science and technology development, the demand for energy is increasing. Meanwhile, fossil fuel sources such as oil, coal, natural gas, hydroelectricity ... are limited, causing people to face the risk of energy shortage. The problem of using energy effectively is a big challenge for scientists and manufacturers. Currently, the trend of using renewable energy and making use of it is a global trend.

Along with the above problem, environmental pollution, greenhouse effect and the destruction of the ozone layer caused by wastes from factories, especially from freon refrigerant, are also urgent issues. top for scientists. There have been many international meetings such as the Kyoto conference and recently the Durban conference taking place on a large scale, of leading countries in technology and equipment to come to the issue of reducing CO2 emissions every year. year, in order to reduce the destruction of the ozone layer and slow down the rate of increase of the greenhouse effect.

The heat of flue gas is a potential source with a relatively high heat potential that is of great interest to humans. In order to have many applications of waste heat in life, it is necessary to have many research directions to use this energy source such as: taking advantage of exhaust heat to generate electricity in cement plants, using waste heat to heat buildings. Research and manufacture of air conditioners using exhaust heat is also a new direction in the trend of the above applications.

Compared with the NH3/H2O - gas/liquid adsorbent - widely used in current absorption chillers, the zeolite - water pair is solid/liquid, so zeolite - water is not evaporating with water in the process of generating steam, the water produced is not mixed with moisture, so the device structure does not need a dehumidifier, so it is simpler and does not require high manufacturing technology.

In this thesis, we only focus on studying adsorption refrigeration using exhaust heat - an abundant energy source, with a relatively high potential (about 2500C on average), but often discarded, with a pair of refrigerants. Refrigeration is water/zeolite used in fruit preservation, vaccines, air conditioning and cold water used in aquatic products.

2. Research objective

On the basis of theoretical and experimental research, an air conditioner model using waste heat energy sources is found, efficient and can be applied in practice.

Gathering theoretical and experimental bases for the implementation of practical applications later.

3. Object and scope of research

The object of the study is an adsorbent using a zeolite-water pair of solvents using exhaust heat.

Research scope: research, calculate, design, manufacture adsorption air conditioners using Zeolite - Water pair of refrigerants using hot water, medium cooling temperature range (above 120C) and in mode air conditioner.

4. Research Methodology

Using the method of analysis, comparison, and evaluation comprehensively.

Research computational theory, combined with experiment.

5. Scientific and practical significance

The practical significance of the project is that it is possible to take advantage of exhaust heat for refrigeration and air conditioning with simple structure, high reliability, low cost, and no environmental pollution.

The research project applies exhaust heat to refrigeration and air conditioning, which will help reduce power consumption in refrigeration systems, significantly reducing wastes that pollute the environment. On that basis, it can be applied to refrigeration and air conditioning, in seafood factories, textile factories, hotels.

6. Structure of the topic

In addition to the introduction and recommendations, the thesis consists of 3 chapters, in which:

Chapter 1: Overview of exhaust fumes and air conditioners using exhaust heat.

Chapter 2: Research, design, calculation, and design of Zeolite adsorption air conditioners - Water using exhaust heat energy.

Chapter 3: Making a model of Water - Zeolite adsorption air conditioner using hot water

CHAPTER 1

OVERVIEW OF WASTE SMOKE HEAT AND REFRIGERATION USE OF EXHAUST THERMAL

1.1. OVERVIEW OF Emissions

1.1.1. Exhaust smoke

1.1.2. Sources of exhaust fumes

1.1.3. Theoretical basis of exhaust smoke recovery

a. Necessary conditions for exhaust smoke recovery

- The heat source has the necessary amount;

- The working agent has a sufficiently high temperature level;

- Stability of exhaust smoke source

- Equipment needs and availability.

b. Exhaust smoke source characteristics

When considering exhaust heat sources, it is necessary to pay attention to the following characteristics, so that reasonable plans can be made.

* Heat source characteristics

* Properties of exhaust smoke

When taking advantage of exhaust heat, we have also reduced its temperature, so it is necessary to pay attention to the dew point of the exhaust smoke. This temperature depends on the sulfur content in the fuel.

1.1.4. Types of exhaust smoke recovery equipment

1.1.5. Plans to make use of exhaust fumes to provide heat for air conditioners

1.1.6. Equipment to utilize exhaust heat

a. Horizontal beam tube heat exchanger

b. Fire tube heat recovery boiler c.Water tube heat recovery boiler

1.2. DIFFICULTY AND DISADVANTAGES OF EXhaust Smoke Recovery SYSTEM

The waste heat sources are sometimes discontinuous, in addition to the asynchronousness of the main system and the system using the exhaust smoke. Therefore, it is necessary to calculate specifically to evaluate, if the resistance is large, it is necessary to install additional pumps, auxiliary fans, and dirt in the recovery devices, so cleaning and maintenance solutions are required.

1.3. OVERVIEW OF CONDITIONER USE THERMAL WASTE FIRE

1.3.1. Air conditioner ejector.

1.3.2. Absorption chiller

a. Diagram of the principle of absorption refrigeration

b. Classification of absorption refrigeration

c. Pros and cons

d. Conclude

1.4. RESEARCH SITUATION IN THE TOPIC OF THE SUBJECT

AT HOME AND OUTSIDE

1.4.1. In the world

1.4.2. In Vietnam

1.5. THEORY OF SUPPLY CONDITIONER

1.5.1. Principle diagram:

1.5.2. Pair of refrigerants used in adsorption refrigeration

a. adsorption theory

b. Adsorbent Materials [8]

c. Water/zeolite adsorbent pair

d. Phase balance of the adsorption process

e. Theories of adsorption [8]

CHAPTER 2

RESEARCH, CALCULATION AND DESIGN OF WATER/ZEOLIT SUPPLY CONDITIONER USE OF THERMAL ENERGY OF EXHAUST

2.1. MODEL BUILDING

2.1.1. Exhaust smoke heat energy source

2.1.2. Schematic diagram of adsorption refrigeration

1- Adsorbent steam generator, 2- condenser, 3- stop valve, 4- reservoir, 5- stop valve, 6- throttle valve, 7- indoor unit, 8- stop valve

Figure 2.1. Actual diagram of H2O/Zeolite adsorption chiller using hot water

2.2. CALCULATION THEORY DESIGN

The calculation and design of hot water heaters, condensers, tanks, evaporators ... are common problems of heat and air conditioning. The new problem here is to determine the amount of charging medium (water and Zeolite) and calculate the design of the steam generator - adsorbent.

2.2.1. Calculation parameters

a. Evaporation pressure P0: (corresponding to t0)

Defined as a conventional vapor compression refrigeration cycle.

b. Condensing pressure PK: (corresponding to tK)

Different from the conventional vapor compression refrigeration cycle: the condensing pressure depends on the temperature and state of the cooling medium; In the adsorption refrigeration cycle, the condensing pressure is the pressure in the steam generator.

2.2.2. Determine the amount of charging medium

a. Determine the amount of water to be loaded

G = Q 0

r(P0 )

, (2.1)

Where: Q0: Necessary cooling capacity of the evaporator, kJ; r(p0): The latent heat of vaporization of water at pressure p0, kJ/kg.

In reserve 20% of the water wetting the pipe, Zeolite ..., the amount of water to be loaded is:

Gload = 1.2 G = 1.2

Q0

r(P0 )

, kg (2.2)

b. Determine the amount of Zeolite loaded

Based on the graph of zeolite adsorption isotherm for water [8], showing the state of zeolite that has adsorbed enough water (point 1 of figure 2.2):

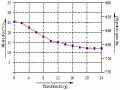

Figure 2.3. Isothermal adsorption of water vapor into Zeolite

2.2.3. Design of steam generator - absorber

a. Request

- Can hold all refill water and refill Zeolite.

- Heat exchanger area and heat transfer coefficient as high as possible (to reduce heating and cooling time).

b. Device structure

c. Calculate

* Size and number of adsorbent tubes

The volume of space between the two sleeves of the absorbers must ensure that all the water inlet and the zeolite can be filled.

* Determine the total amount of heat supplied to the steam generator

The total amount of heat Q gn supplied to the steam generator includes the amount of heat Q gn1 for heating the device and Zeolite from T a2 to T g2 ; The amount of heat Q gn2 heats the water refrigerant from T a2 to T g1 and heats the water to completely vaporize and lose heat to the environment.

Q gn = Q gn1 + Q gn2 , kJ (2.3)

c1. The amount of heating for the device and Zeolite Q gn1

Q gn1 = (M TB C TB + M Z C Z )(T g2 – T a2 ) , kJ (2.4)

In there:

- M TB , C TB , M Z , C Z are the mass and specific heat capacity of the device and the Zeolite, respectively (C Z 0.06 kJ/kgK [9])

- T g2 T gn – 5 ; T gn : heating hot water temperature

- T a2 T W + 5 : cooling water temperature

c2. Amount of heating and vaporizing water refrigerant Q gn2

Q gn2 = M n [C n (T g1 – T a2 ) + r g ] , kJ (2.5)

In there:

- M n , C n are the mass and specific heat capacity of the water refrigerant, respectively.

- t g1 = 70 0 C: temperature of steam starting to separate from Zeolite

- r g : latent heat of water vaporization at T g1

CHAPTER 3

PRODUCING MODEL OF WATER SUPPLY/ZEOLIT CONDITIONER USE HOT WATER

From the requirements, the project builds a water/zeolite adsorption air conditioner model for refrigeration and air conditioning, thereby calculating and designing the main equipment of the refrigerating system such as: amount of charging refrigerant, equipment adsorbent - steam generator, condenser, heating device..., to serve as a basis for making realistic models.

3.1. CHARACTERISTICS OF ADDITIONAL CONDITIONER CONDITIONER

Figure 3.1. Actual diagram of H 2 O/Zeolite adsorption chiller using hot water

3.2. TECHNICAL REQUIREMENTS

+ Cool 1.5 liters of water from 25 0 C to a temperature of 12 0 C.

+ Heating hot water has a temperature of (88 90) 0 C.

+ Use H 2 O/Zeolite adsorption air conditioner to work intermittently.

+ Cooling water for the adsorbent has a temperature of 25 0 C.

+ Air-cooled condenser.

+ Located in Quang Ngai city, the average summer temperature is 37.8 0 C.

3.3. CALCULATION AND DESIGN MODEL OF EXTRACTOR CONDITIONER

3.3.1. Choose evaporator

+ Volume of water to be cooled:

V = d 2 /4L = 3.14 x 0.0736 2 / 4 x 0.36 x 1,000 = 1.53 liters :

Assure requirements

a. Total amount of cold needed

Heat loss due to water cooling:

Q n = GC t = 1.5 x 4.186 x (25 – 12) = 81.63 kJ

+ Heat loss due to cooling of the shell:

Q v = G v C v t = 1.7 x 0.5 x (25 – 12) = 11.05 kJ

In there:

G v : weight of tank shell & connecting pipe, weighing 1.7kg; C v : specific heat capacity of stainless steel (see iron equivalent) 0.5 kJ/kgC

+ Taking into account heat loss to the environment and storage (see about 20% ) , the required amount of cold for the system is:

Q l = 1.2 (Q n + Q v ) = 1.2 x (81.63 + 11.05) = 111.2 kJ

b. Water chilling time

Heat exchanger area:

Reserve, see if the liquid is submerged only 1/3 of the height of the inner tube.

So, the heat exchanger area of the vessel is:

F = 0.076 x 3.14 x 0.36/3 + 0.076 2 x 3.14 /4 = 0.033 m 2

+ Evaporation temperature:

t 0 = t fc – 5 = 12 – 5 = 7 0 C

+ Average temperature of water to be cooled:

t f = (25 + 12) / 2 = 18.5 0 C

Heat transfer coefficient of the evaporator:

k = 1

n_

first

1___

t_

Where: - = 1.2mm : thickness of inner tube

- = 15.6 W/mK: coefficient of thermal conductivity of stainless steel.

* t : heat dissipation coefficient of water cooled by natural convection.

Parameters of water cooled at 18.5 0 C [4]:

= 1,051.10 -6 m/s 2 ; = 0.59525 W/mK; Pr = 7,395; β = 0.003431 K -1 .

According to [8], the heat transfer coefficient of natural convection water in infinite space:

Grat-foam standard:

Gr _

g . . _ t . _ l 3

2_

9,81.0.003431.11,5.0.36 3

1,051.10-62__

1,634.1010_

With l = h = 360mm: inner tube height.

Product Gr.Pr = 1.634.10 10 x 7.395 = 1.2.10 11 , Π[ 2.10 7 10 13 ]

so we have: n = 1/3 and C = 0.135.

So: Nu = C(Pr.Gr) n = 0.135 x (1,2.10 11 ) 1/3 = 665.9. Derived from:

Nu ._ _ 665,9.0,59525_ _

= 1,100 W/m 2 K

t l 0.36